Biodegradable Plastic Materials Do Not Biodegrade In The Ocean

For the first time, new research from UC San Diego’s Scripps Institution of Oceanography monitored the capacity of natural, synthetic, and hybrid textiles to decompose immediately in the ocean. The study was published May 24 in the journal PLOS One.

In an experiment done off the Ellen Browning Scripps Memorial Pier, lead author Sarah-Jeanne Royer discovered that textiles made of natural and wood-based cellulose deteriorated within a month. Even after being immersed in the water for more than a year, synthetic textiles, including so-called biodegradable plastic materials like polylactic acid (PLA), and the synthetic components of textile blends, showed no deterioration.

“This study shows the need for standardizing tests to see if materials promoted as compostable or biodegradable actually do biodegrade in a natural environment,” said Royer, who performed the research while a postdoctoral scholar in the Dimitri Deheyn laboratory at Scripps Oceanography. Royer currently remains affiliated with Scripps Oceanography as a visiting scholar from Hawaii Pacific University. “What might biodegrade in an industrial setting does not necessarily biodegrade in the natural environment and can end up as marine and environmental pollutants.”

The devastating effects of fast fashion can be seen worldwide in photographs of landfills in Chile and Kenya piled high with mountains of trashed garments. These materials may linger in the environment for decades to millennia and make up an estimated 68 million tons, or 62 percent, of all textiles produced today. Microfibers from synthetic fabrics that fall out regularly while being worn and washed contribute to plastic pollution. Most washing machines are not built with filters to catch microfibers, which eventually wind up in wastewater and the ocean.

Bio-based polymers, which are created from renewable resources like sugar cane or cornstarch, have been promoted as a possible solution to the plastic issue. One such polymer in the market for bio-based plastics is PLA, which is often advertised as compostable and biodegradable. Given its widespread usage as a substitute for materials based on oil, the research team decided to employ this cloth.

Ten different kinds of fabrics, including wood-based cellulose (commercially known as Lyocell, Modal, and Viscose), natural cellulose (organic virgin cotton and non-organic virgin cotton), bio-based plastic (PLA), oil-based plastic (polyethylene terephthalate and polypropylene), and fabric blends of Lyocell combined with polyester and polypropylene, were used in the experiment. All of these are often used in the textile sector. One kind of polyester that is often offered as a recycled textile is polyethylene terephthalate. Textiles, carpets, geotextiles, packaging materials, and disposable medical textiles like masks all employ polypropylene.

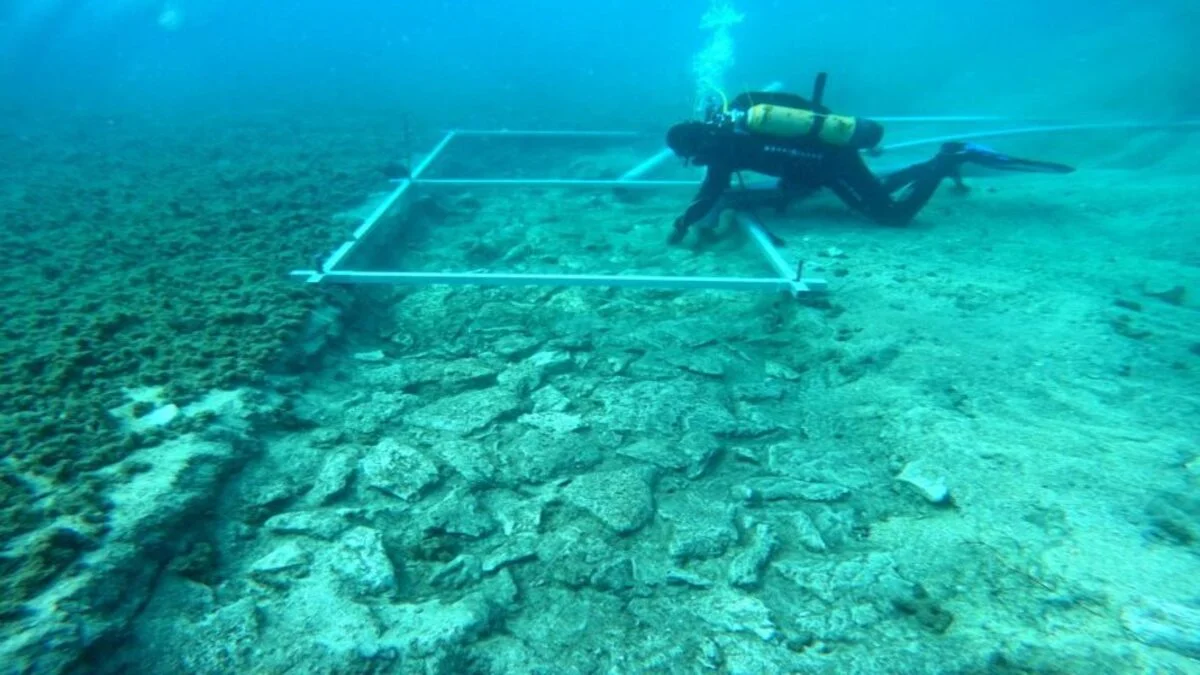

The textile samples were put in flow-through containers positioned on the ocean bottom and at a depth of about 10 meters (32 feet) below the water’s surface. Every seven days, samples were inspected, photos were taken, and tiny portions were extracted from duplicate samples for further lab testing. This included high-resolution fiber examination with scanning electron microscopy and fiber chemical and molecular structure analysis using Raman spectroscopy. After that, the samples were again submerged, this time for 196 days at the bottom and 231 days at the water’s surface.

Following the completion of the Scripps Pier experiment, the samples were transferred to Scripps Oceanography’s Experimental Aquarium, where they were subjected to regulated conditions of flowing saltwater. The oil-based and bio-based fabrics showed no signs of disintegration even after 428 days, but the natural, cellulose-based textiles regularly degraded in 30-35 days.

“The natural, cellulose-based materials would disintegrate in about one month, so we would exchange for a new sample after the old one disintegrated,” said Royer. “The natural samples were replicated five times, while the plastic samples remained the same for more than a year.”

Senior author of the research and Scripps marine scientist Dimitri Deheyn determined each fiber’s size and structure by examining the samples under an electron microscope. While the diameter of the plastic fibers stayed constant and showed no signs of biodegradation, the natural fibers became smaller with time. Francesco Greco, a co-author of the study, used Raman spectroscopy to examine the structural-chemical deterioration of the fibers at Northwest University in China’s Department of Geology. While bio- and oil-based plastics remained constant, Greco, who is now at the Weizmann Institute of Science, discovered substantial alterations in the chemical fingerprint of the cellulose-based polymers.

Compared to textiles manufactured exclusively of synthetic polymers, fiber blends—which combine natural fiber strands with bio- or oil-based plastic strands—are often touted as more environmentally friendly. However, as this research shown, only the natural component of the fiber deteriorated, leaving the plastic component of the mix in tact.

Additionally, an independent business tested the same kind of textiles in a closed-system bioreactor, which simulates a marine environment in an enclosed, indoor system. As a substitute for testing biodegradability, the bioreactor permitted measurements of the percentage of carbon dioxide generated by microbial activity using the textiles as nutrients. While the oil-based and bio-based fibers exhibited no signs of biodegradation, the cellulose-based materials demonstrated full biodegradation in only 28 days.

The authors of the study note that oil-based polyethylene terephthalate and polypropylene, as well as the bio-based polylactic plastic, which is marketed as an environmentally friendly material, are significant sources of pollution caused by humans. It is important to investigate further how these materials behave in the environment.

“This comparative study highlights how crucial our language is around plastics,” said Deheyn. “Indeed, a bioplastic like PLA, commonly assumed to be biodegradable in the environment because it contains the prefix ‘bio,’ is actually nothing like that.”

Royer and colleagues believe that due to these findings, customers will be more conscious of the influence of their own decisions.

“Consumers who are concerned about microfiber plastic pollution should be mindful of the materials they are buying,” said Royer. “We should all aim to buy fewer garments, opt for high-quality, cellulose-based materials like cotton, merino or wool that will last longer, or look to more circular and sustainable options that repurpose items like clothing swaps and Buy Nothing groups.”

The Walter Munk Foundation for the Oceans, Lenzing, and Preserve Calavera and the Biomimicry for Emerging Science and Technology (BEST) Initiative supported the work from the Deheyn lab. The Chinese government’s Young Thousand Talents Plan assisted with the Raman analysis.

The study’s co-authors include Michaela Kogler from Lenzing and Royer, Deheyn, and Greco.

Click here for the original study.

Disclosure: This post may contain affiliate links, which means that DIVEMONDO may receive a small commission if you make a purchase using these links. As an Amazon Associate this website earn from qualifying purchases.

Leave a Reply